Installing Spray Foam Insulation in the Winter

It’s the middle of winter, and now that the temperatures have dropped, you realize your home’s insulation just isn’t cutting it. There are drafts all around your house, and your heating bill is climbing towards the clouds. If the thought of spending the next few months shivering away and spending far too much on your ever-climbing energy bill doesn’t sound appealing, you may want to consider installing spray foam insulation—one of the most effective insulation options. To learn about the process of installing spray foam in the winter, continue reading.

Challenges of Applying Spray Foam in the Winter

Ideally, spray foam insulation should be installed during the warmer months of the year. Once temperatures start dipping, the process of installing spray foam insulation becomes a lot more challenging. For a successful spray foam insulation installation, the surface temperature of the application side typically needs to fall between 60 and 80 degrees Fahrenheit. If temperatures are below that range, there’s a greater potential for equipment breakdowns and a larger chance that the foam will pop, shrink, and fail to adhere properly to the substrate.

That said, it is possible to successfully install spray foam insulation when temperatures dip below this range. Below, we’ll address some of the extra accommodations you can make to overcome these challenges.

Methods for Overcoming the Challenges

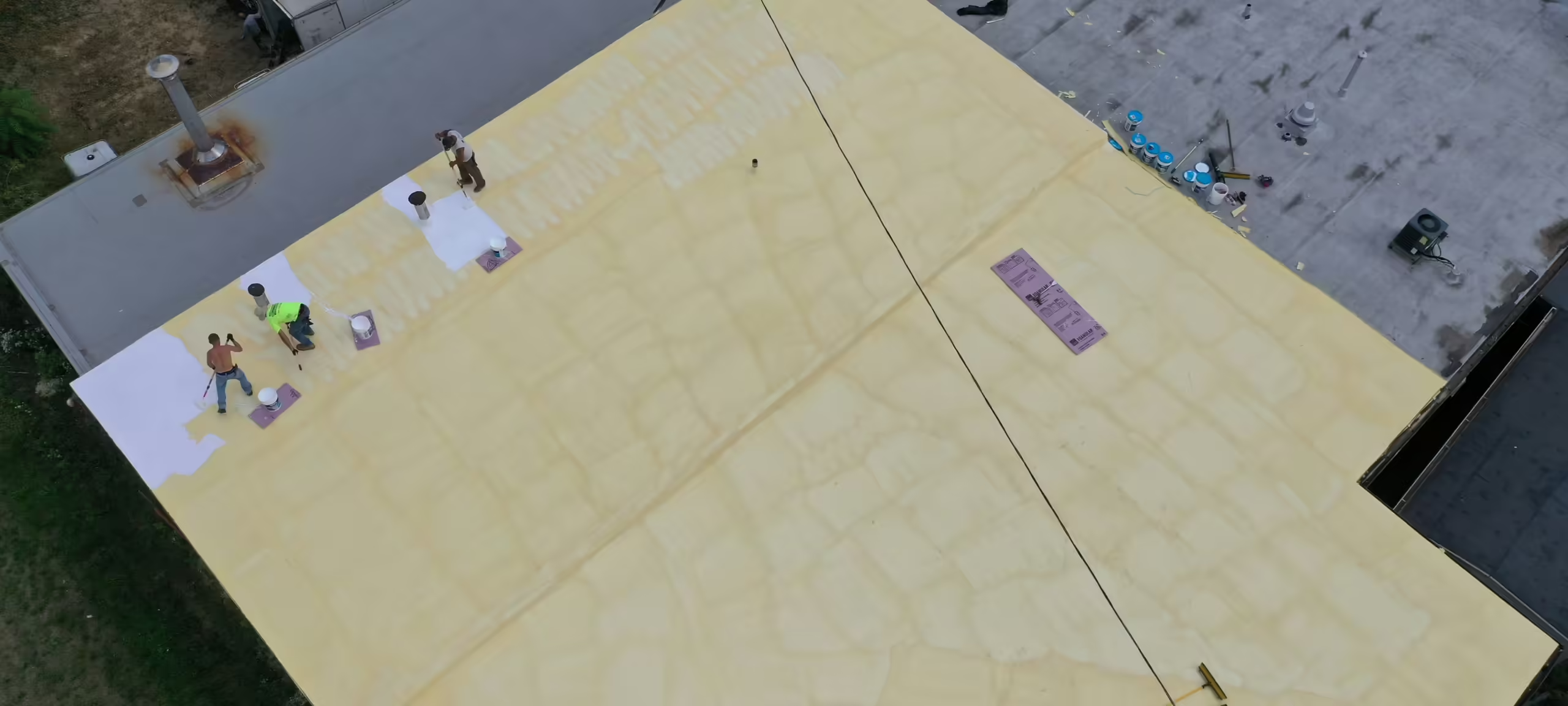

Installing spray foam during the winter is more challenging, but you can increase the potential for a successful installation in several ways. One way to successfully apply spray foam insulation in the winter despite the unideal conditions is to use a winter blend of spray foam. Closed-cell spray foams can be formulated into a winter blend that allows them to withstand colder environmental and surface temperatures. If you want to install open-cell spray foam insulation, however, it’s not possible to create a winterized formulation. Instead, you must create a suitable environment at the installation site.

In addition to using the right blend of spray foam, making application adjustments for the lower ambient temperature is also important. When you’re applying spray foam when temperatures are colder, it’s important to keep the hose off any ice, snow, or concrete, as doing so will cause heat to be drawn out more quickly. Minimizing the distance between the rig and the application site will also reduce heat loss by reducing the amount of hose exposed to the elements.

On especially cold days, using a smaller mix chamber in the application gun can keep the material warmer. Doing so will slow the material’s flow so that it stays in the heated system longer. It’s important to note the installation process of spray foam is generally much longer during the winter due to the need for such accommodations.

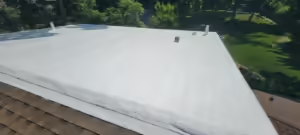

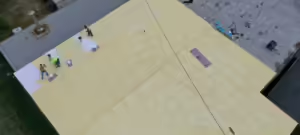

Installing spray foam insulation is a complicated and potentially dangerous process if you don’t have the necessary equipment and expertise. As such, it’s always best to hire a professional spray foam insulation contractor—especially during the winter, when the installation process is even more complex. Paragon Protection is a leading spray foam insulation contractor in Lake Zurich and the greater Chicago area. To learn more about our services and how we became the most trusted insulation company in Chicagoland, contact us today.

Professional Insulation Services

Professional Insulation Services Attic Insulation Services

Attic Insulation Services Basement Insulation

Basement Insulation Commercial Insulation

Commercial Insulation Crawl Space Insulation

Crawl Space Insulation Exterior Wall Insulation

Exterior Wall Insulation Garage Insulation

Garage Insulation Interior Wall Insulation

Interior Wall Insulation Shed Insulation

Shed Insulation Power Washing

Power Washing Sealcoating

Sealcoating Backup Power Generators

Backup Power Generators Lake County Insulation

Lake County Insulation Spray Foam Insulation Guides

Spray Foam Insulation Guides Insulation Guide

Insulation Guide Home Improvement & Maintenance Guide

Home Improvement & Maintenance Guide