The Difference Between Spray Foam Densities

When choosing the type of spray foam insulation to use for your application, there are numerous factors to consider. One such factor is density. There are three different levels of density one can choose from when it comes to spray foam insulation—high-density spray foam insulation, medium-density spray foam insulation, and low-density spray foam insulation. Each different spray foam density is designed for a particular task and offers unique advantages. As such, it is important to familiarize yourself with the different densities so that you can choose the correct spray foam insulation type for your project. Here’s a guide to the difference between spray foam densities to help you determine which one is right for your application.

High-density spray foam insulation

High-density spray foam insulation has the densest structure of all spray foam insulation types. Due to its high density, more material is needed to cover and insulate an area. For each cubic foot of high-density spray foam insulation, roughly 3 lbs. of closed-cell foam is used. In comparison to lower-density foams, high-density spray foam insulation doesn’t expand as much because of its denser structure. The R-value of high-density spray foam starts at around 5.5 per inch.

Uses

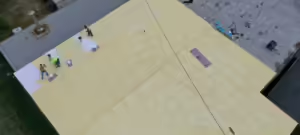

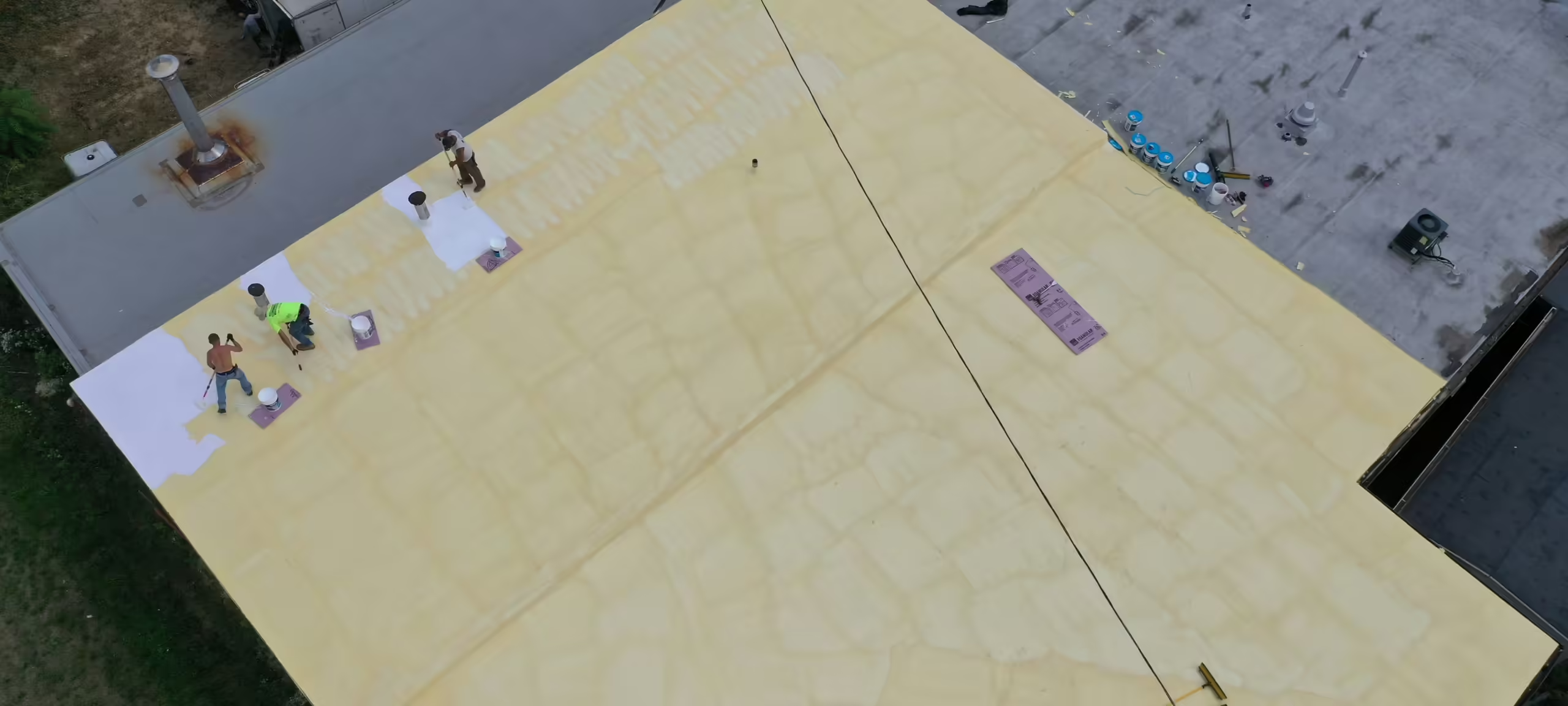

High-density spray foam insulation is used when an extremely high R-value and extra strength is needed. Typically, high-density spray foam insulation is often employed for exterior and roofing applications in commercial or industrial construction.

Benefits

High-density spray foam is applied in a continuous manner, which results in a seamless application. Because of its impeccable thermal resistance properties, high-density spray foam insulation can significantly help reduce energy costs inside a structure throughout the lifetime of the roof it is applied to.

In addition to its exceptional insulating qualities, high-density spray foam insulation can also help protect and extend the life of roofing and exterior structures. Once bonded to a surface, high-density spray foam insulation can help reduce wind damage by increasing the structure’s resistance to wind uplift. Plus, it also helps protect the roofing against heat and water infiltration while simultaneously strengthening and providing load support to the structure it is applied to.

Medium-density spray foam insulation

Medium-density spray foam insulation requires around 2 lbs. of closed-cell spray foam per cubic foot. It has a high R-value, which starts at 5.7 per inch.

Depending on the application, medium-density spray foam insulation can be applied as either low- or high-pressure two-component spray foam. For larger projects such as renovations or building construction, medium-density spray foam will likely be applied as high-pressure, two-component spray foam. For insulating small to midsized areas such as around ductwork or piping, medium-density spray foam is typically applied as low-pressure, two-component spray foam.

Uses

Medium-density spray foam insulation is frequently used for continuous insulation, unvented attic applications, and interior wall cavity fill. It is also the most common type of spray foam insulation used in crawlspaces and in the construction of new homes. Due to its high R-value of 5.7 per inch, medium-density spray foam insulation is often used in situations where the maximum possible R-value insulation per inch is needed.

Benefits

Medium-density spray foam insulation provides high-tensile strength, which means it will be able to withstand large amounts of stress without breaking—a beneficial quality for applications that require a durable insulation option. In addition, medium-density spray foam insulation also provides a high bond strength. In other words, medium-density spray foam insulation adheres well to the surface it is applied to and requires a substantial amount of stress to separate the insulation from its base.

Further, medium-density spray foam insulation provides low vapor penetration. As such, its insulation qualities aren’t typically impaired when exposed to moist environments or rain.

As previously stated, medium-density spray foam insulation also has an exceptionally high R-value. The R-value of an insulator measures how well it is able to resist the conductive flow of heat—aka how effective it is as an insulator. At an impressive R-value of 5.7 per square inch, medium-density spray foam insulation is optimal for tight applications that require the highest possible R-value in the least amount of space.

Low-density spray foam insulation

Also known as open-cell foam or half-pound foam, low-density spray foam insulation utilizes around 0.5 lbs. of open-cell foam per cubic foot. This insulation material is full of cells that are purposefully left open, making the foam softer, less dense, and more flexible.

R-values for low-density spray foam insulation start at roughly 3.6 per inch. Like medium-density spray foam insulation, low-density spray foam insulation can be applied as low- or high-pressure, two-component polyurethane spray foam.

Uses

Low-density spray foam insulation is most commonly used for interior applications. Common uses for low-density spray foam insulation include wall cavities, unvented attics, basement walls, the underside of roof decks, ducts, ceilings, and crawl spaces. In addition, low-density spray foam insulation is also frequently used during construction to fill wall cavities.

Benefits

An effective insulator, it provides continuous insulation and an air-sealing barrier to the surface it is applied to. As such, it can effectively seal airflow through joints, seams, cracks, and cavities. While low-density spray foam insulation acts as an air barrier, it is permeable to moisture and vapor because of its open-cell structure. By allowing for moisture permeability, low-density spray foam insulation helps facilitate moisture management as well as bi-directional drying when necessary.

The large open-cell structure of low-density spray foam insulation allows it to stay relatively soft and provides some flexibility to the cured foam. This flexibility can be beneficial as it allows the insulation to maintain its efficiency even as the structure it is applied to shifts and settles over time. As a bonus, the soft texture of low-density spray foam insulation also helps absorb sound in the area it is applied to.

If you’re interested in installing spray foam insulation in your home or commercial building, make sure to enlist the help of a trained insulation installation professional. Spray foam insulation installation involves complex processes that require specialized equipment and expertise. At Paragon Protection, our trained contractors have the experience necessary to help you determine the appropriate spray foam insulation density for your application and install it safely and efficiently. For more information regarding our spray foam insulation contractors in McHenry, Wauconda, Lake Zurich, and Crystal Lake, contact us today.

Professional Insulation Services

Professional Insulation Services Attic Insulation Services

Attic Insulation Services Basement Insulation

Basement Insulation Commercial Insulation

Commercial Insulation Crawl Space Insulation

Crawl Space Insulation Exterior Wall Insulation

Exterior Wall Insulation Garage Insulation

Garage Insulation Interior Wall Insulation

Interior Wall Insulation Shed Insulation

Shed Insulation Power Washing

Power Washing Sealcoating

Sealcoating Backup Power Generators

Backup Power Generators Lake County Insulation

Lake County Insulation Spray Foam Insulation Guides

Spray Foam Insulation Guides Insulation Guide

Insulation Guide Home Improvement & Maintenance Guide

Home Improvement & Maintenance Guide